Make Predictive Maintenance Easy With Real-Time Control

Identify problems in real time, before they cause downtime

To make true predictive maintenance a reality, intelligent manufacturers need to be able to do it all…

Ingest and process sensor data at scale and in real time

Trigger actions to automatically maintain SLAs

Use ML to improve outcomes over time

Achieve 99.999% uptime

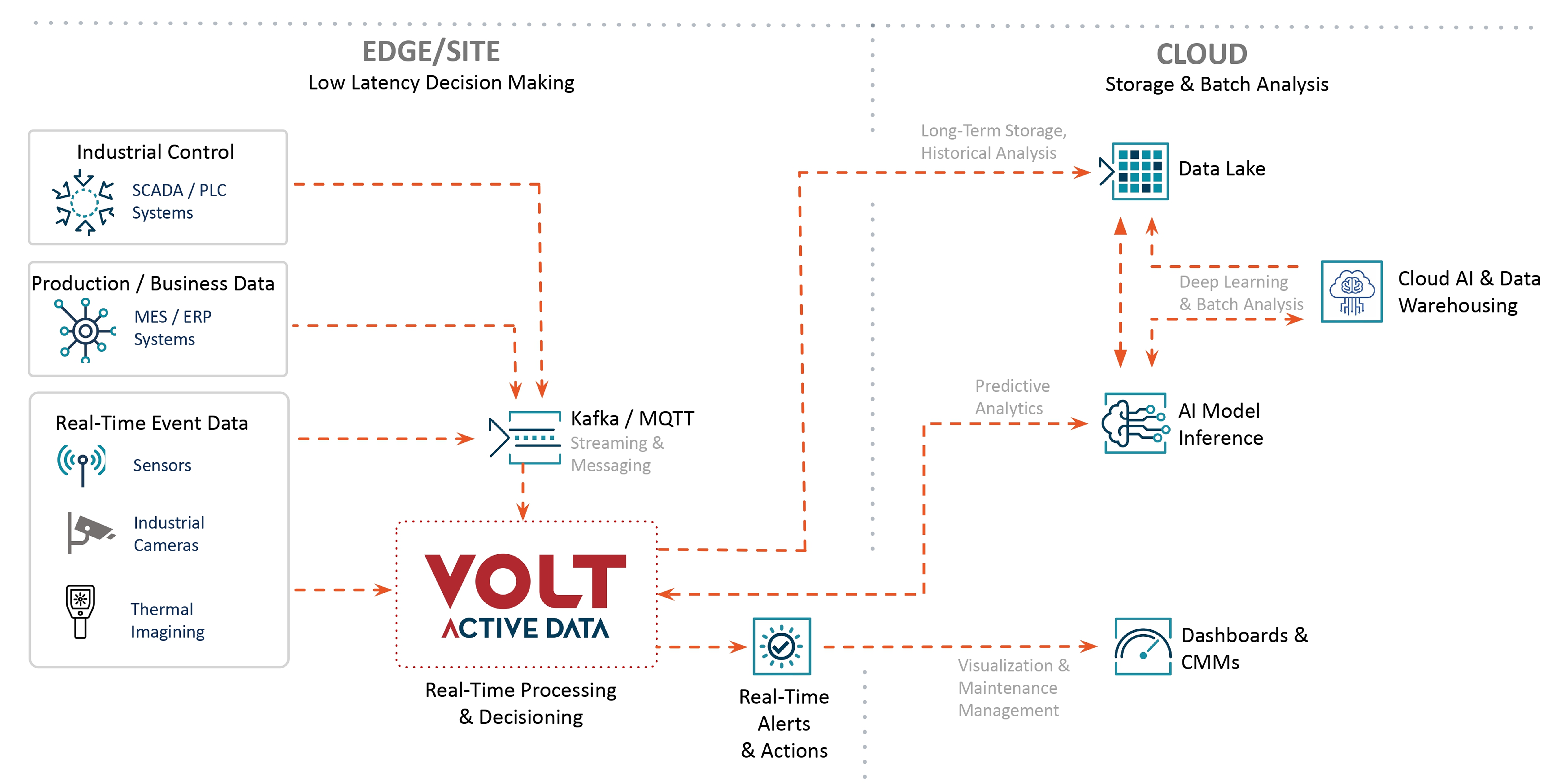

Reference Architecture: Predictive Maintenance

The Intelligent Manufacturing Challenge

Intelligent manufacturers, including and especially auto manufacturers, face a massive and constant flood of data. Their choice? Process it quickly for a huge competitive advantage via predictive maintenance or get overwhelmed and lose out. Losing out is not an option. In the end, your smart factory is only as smart as the system that controls it. You need a command and control layer that enables you to control your floor’s assets in real time to optimize efficiency and production, without having to add complexity or layers or cost.

Why Volt For Intelligent Manufacturing

Volt Active Data is the real-time data processing platform that empowers Industrial IoT solutions with instant decision-making, scalability, and reliability. By combining streaming, transactional, and AI-driven data, Volt helps companies unlock new levels of efficiency and innovation, enabling predictive maintenance, quality control, and production optimization.